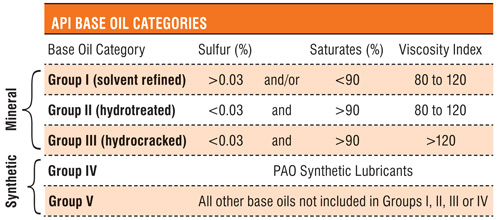

Almost every lubricant used in plants today started off as just a base oil. The American Petroleum Institute (API) has categorized base oils into five categories (API 1509, Appendix E). The first three groups are refined from petroleum crude oil. Group IV base oils are full synthetic (polyalphaolefin) oils. Group V is for all other base oils not included in Groups I through IV. Before all the additives are added to the mixture, lubricating oils begin as one or more of these five API groups.

Group I

Group I base oils are classified as less than 90 percent saturates, greater than 0.03 percent sulfur and with a viscosity-index range of 80 to 120. The temperature range for these oils is from 32 to 150 degrees F. Group I base oils are solvent-refined, which is a simpler refining process. This is why they are the cheapest base oils on the market.

Group II

Group II base oils are defined as being more than 90 percent saturates, less than 0.03 percent sulfur and with a viscosity index of 80 to 120. They are often manufactured by hydrocracking, which is a more complex process than what is used for Group I base oils. Since all the hydrocarbon molecules of these oils are saturated, Group II base oils have better antioxidation properties. They also have a clearer color and cost more in comparison to Group I base oils. Still, Group II base oils are becoming very common on the market today and are priced very close to Group I oils.

Group III

Group III base oils are greater than 90 percent saturates, less than 0.03 percent sulfur and have a viscosity index above 120. These oils are refined even more than Group II base oils and generally are severely hydrocracked (higher pressure and heat). This longer process is designed to achieve a purer base oil. Although made from crude oil, Group III base oils are sometimes described as synthesized hydrocarbons. Like Group II base oils, these oils are also becoming more prevalent.

The Changing Use of Base Oils

A recent study on the use of base oils in today’s plants in comparison to a little more than a decade ago found a dramatic change has occurred. Present-day Group II base oils are the most commonly used base oils in plants, making up 47 percent of the capacity of plants in which the study was conducted. This compared to 21 percent for both Group II and III base oils just a decade ago. Currently, Group III accounts for less than 1 percent of the capacity in plants. Group I base oils previously made up 56 percent of the capacity, compared to 28 percent of the capacity in today’s plants.

Group IV

Group IV base oils are polyalphaolefins (PAOs). These synthetic base oils are made through a process called synthesizing. They have a much broader temperature range and are great for use in extreme cold conditions and high heat applications.

| 57% | of lubrication professionals use both synthetic and mineral-based lubricants in their plant, according to a recent poll at machinerylubrication.com |

Group V

Group V base oils are classified as all other base oils, including silicone, phosphate ester, polyalkylene glycol (PAG), polyolester, biolubes, etc. These base oils are at times mixed with other base stocks to enhance the oil’s properties. An example would be a PAO-based compressor oil that is mixed with a polyolester. Esters are common Group V base oils used in different lubricant formulations to improve the properties of the existing base oil. Ester oils can take more abuse at higher temperatures and will provide superior detergency compared to a PAO synthetic base oil, which in turn increases the hours of use.

any engine oil

LUBRICATING OIL

FORMULATIONS

ENCYCLOPEDİA

is enough.

LUBRICATING OIL FORMULATION ENCYCLOPEDIA has many formulations of greases, complex grease, lithium grease production,sodium greases formula, formulation,multigrade engine oils manufacturing process,motor oils making, gear oil production, synthetic engine oils,semi synthetic motor oils,gasoline oils,diesel oils production process,composition of turbine oils,transmission oil manufacturing, production of cycle motor engine, tractor oils,mineral based motor engine production,heat transfer oils, slideway oils formulation, formulations, cutting oils formula,formulas grinding oils,mould oils manufacturing process and etc.

All lubricating oils in the encyclopedia are producible easily.You need no help and no technıcal support. The encyclopedia is enough to produce lubricating oils and engine oils itself.

LUBRICATING OIL

FORMULATIONS

ENCYCLOPEDIA

is written clear and understandable.

HARD BOOK E BOOK

RELATED TAGS: What is engine oils,making synthetic diesel engine oil,semi synthetic engine oil manufacturing process,mineral based engine oil production, heavy duty engine oil formulation,high performance engine oil formula,formulas,properties of motor oils,synthetic motor oil msds, analysis,composition of engine oils,additives of motor oils, mineral engine oil formulation,make semi synthetic diesel engine oil, base oils,synthetic base oils,light neutral oil,heavy neutral oil,performance additives package, properties of diesel engine oil, how to formulate engine oils, types of engine oils, synthetic motor oils,ingredients of engine oils,compounds of engine oils, index of motor oil,characteristic of motor oils,application of motor oils,combination of synthetic engine oils.

SOLVERCHEM PUBLICATIONS

|

|

|

|

|

|